Product Details

Compact Wire Ropes with Crimped Outer Strands

Compacted wire rope with decreased diameter yet increased tensile strength

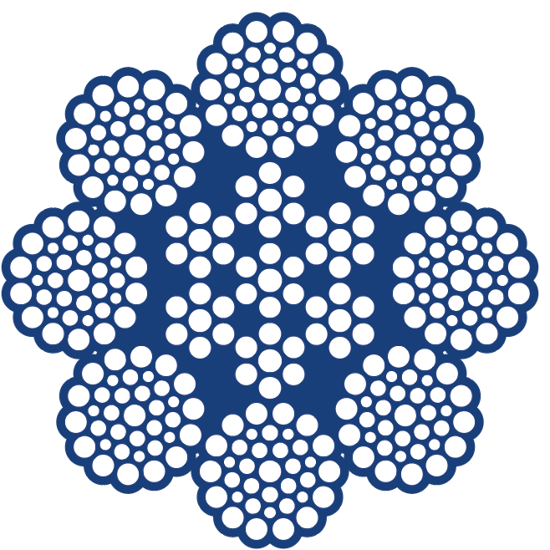

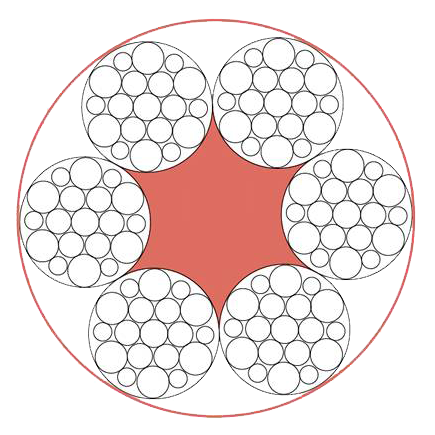

Compact wire rope is composed of several wire strands which have gone through crimping wheels to compress and shape the individual wires to form compacted structures or reduce diameters before laying strands around the core. Taking advantage of the compacting process, the surface of outer wires is flattened and the contact area between strands is increased.

Feature:

- Increased wear resistance of wires.

- Smoother bearing surface than traditional wire ropes.

- Increased tensile strength and lateral compression strength.

- Increase metal cross sectional area.

- Decreased blocks groove wearing.

- Decreased construction stretch.

- Less contact pressure onto the sheaves and drums.

- Better fatigue life and low deformation.

- Capable to withstand high load and sock load.

- Easy to handle.

Application:

- Whip hoist rope.

- Pillar crane rope.

- Deck crane rope.

- Offshore crane rope.

- Other various hoist ropes.

- Mining ropes.

- Machinery.

- Marine fishing applications.

Three main types of compacted wire ropes can be offered: general compacted, fiber infilled and plastic injected steel wire rope:

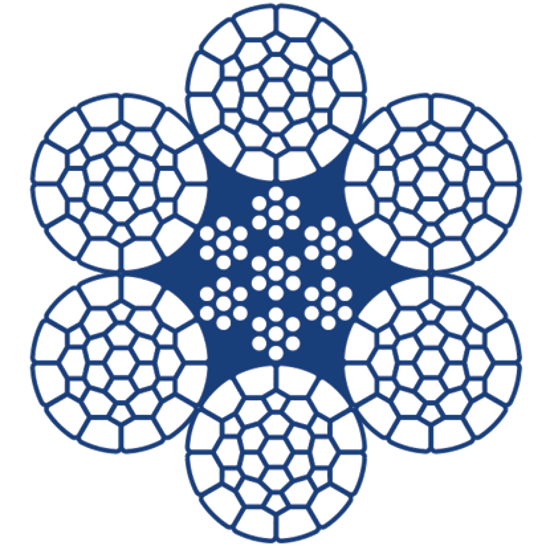

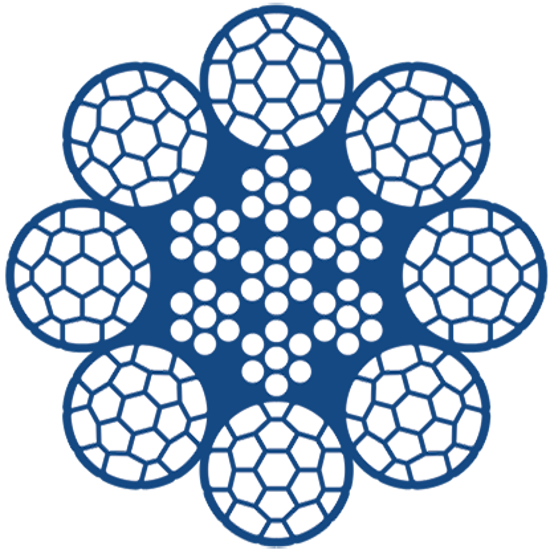

- General compacted wire rope – This is the standard type of wire rope which is construction of normal inner core wire and compacted outer wire or strands.

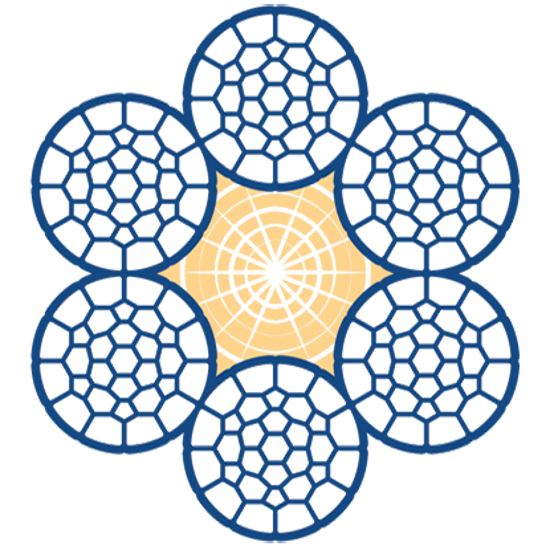

- Fiber infilled wire rope – With compacted outer surface and added fibers & lubricant inside the rope, fiber infilled wire rope can efficiently reduce the friction between outer strands and inner core, protect the core form corrosion as well as maintain the stability of the rope.

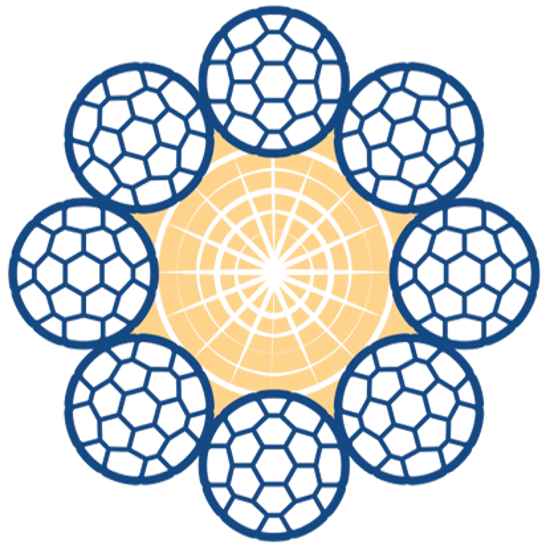

- Plastic injected wire rope – It features special made plastic which is injected in the core of wire for separating the independent wire rope core and each strand totally. As an excellent alternative of traditional lubricant, the plastic reduces the friction and maintenance works.

It is the wire strands, not the total rope that go through the compacting process. But as your request, swage compaction can be applied to the entire rope for flat surface and closer strand gaps.

No comment