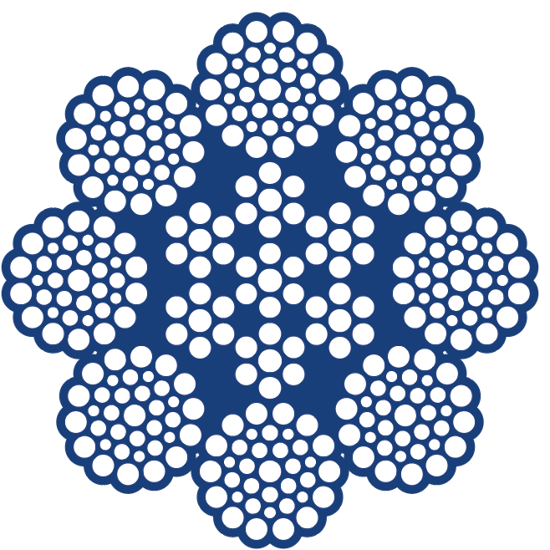

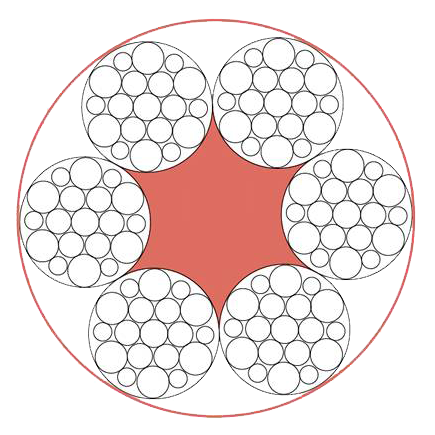

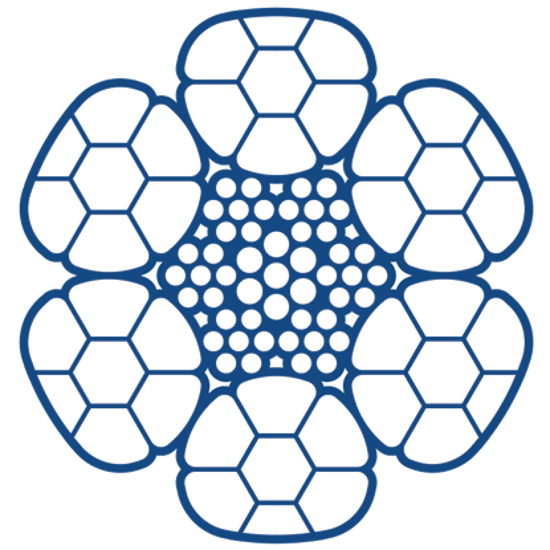

6×26 SWAGED WIRE ROPES

What is Swaged Wire Rope?

Swaged wire rope is made by compacting regular wire rope into a smaller, denser diameter. Density is key, because the higher weight per foot is what produces the increased strength and toughness you get with swaged wire rope.

Who Uses Swaged Wire Rope?

For us, the biggest market is logging although swaged wire rope is used by folks in various industries all over the world. Swaged wire rope–and Impact Swaged Wire Rope, which is even more stout–holds up extremely well to rough, rugged use. It really shines in skyline, guyline, dropline and drumline applications. This is not only due to its strength, but also because it is smoother and therefore spools better and is less prone to abrasion.

No comment