5 Meters 304 Stainless Steel Wire Rope 2mm 3mm 4/5/6/8mm Wire rope pvc coated Transparent Clothesline 7*7

LKING STEEL LIMITED manufacture, stock and supply robust and stable Stainless Steel Wire rope pvc coated to help give your operation that extra level of safety. Plastic coated wire rope coated is proven tobe a versatile and robust type of rope and is suitable for both indoors and outdoors use. The PVC coating is added to stainless steel, galvanized steel and nylon and is smooth to the touch and can easily be stripped back where required.

For more information regarding plastic coated wire rope contact LKS today. We can discuss your requirements and place an order for whatever length you require, pricing is by the meter.

LKS Stainless offers a complete line of Stainless Steel Wire Rope for marine, industrial and architectural applications. All of our stainless wire is made from 316 and 304 stainless steel. Our wire rope product line also includes both Black PVC Coated Wire & White quality plastic coated Stainless Steel Wire Rope.

Material:304 stainless steel & PVC

Prompt:Diameter 2~6mm means the diameter of stainless steel & plastics,the right is the diameter of bare wire rope

What is wire rope specifications construction?

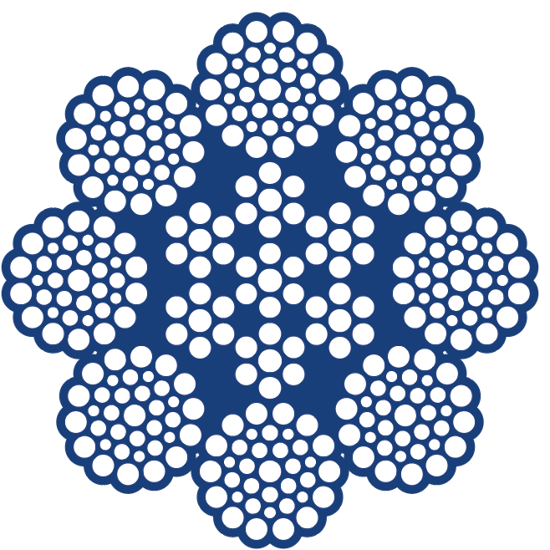

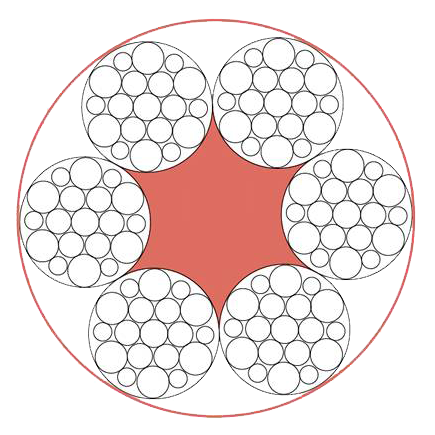

Wire rope classification is done by the number of strands as well as by the number of wires in each strand, e.g., 6 x 7, 6 x 19, 6 x 37, 8 x 19, 19 x 7, etc. However, these are nominal classifications that may or may not reflect the actual construction. For example, the 6 x 19 class includes constructions such as 6 x 21 filler wire, 6 x 25 filler wire, and 6 x 26 Warrington Seale. Despite the fact that none of the three constructions named have 19 wires, they are designated as being in the 6 x 19 classification.

Hence, a supplier receiving an order for 6 x 19 rope may assume this to be a class reference, and could possibly furnish any construction within this category. But, should the job require the special characteristics of a 6 x 25 filler wire, and a 6 x 19 Seale is supplied in its stead, a shorter service life may result.

To avoid such misunderstandings, the safest procedure is to order a specific construction. In the event that the specific construction is not known or is in doubt, the rope should be ordered by class along with a description of its end use.

Identification of wire rope in class groups facilitates selection on the basis of strength and weigh/foot since it is customary domestic industry practice that all ropes (from a given manufacturer) within a class have the same nominal strength and weigh/foot. As for other-functional-characteristics, these can be obtained by referencing the specific construction within the class.

Only three wire ropes under the 6 x 19 classification actually have 19 wires: 6 x 19 two-operation (2-op), 6 x 19 Seale (S), and 6 x 19 Warrington (W). All the rest have different wire counts. In the 6 x 37 class there is a greater variety of wire constructions. The commonly available constructions in the 6 x 37 class include: 6 x 31 Warrington Seale (WS), 6 x 36 WS, 6 x 41 Seale Filler Wire (SFW), 6 x 41 WS, 6 x 43 Filler Wire Seale (FWS), 6 x 46 WS, etc. – none of which contain exactly 37 wires.

WIRE ROPE CLASSIFICATIONS

| Classification | Outer Strands | Wires/Strand | Maximum No. Outer Wires |

|---|---|---|---|

| 6×7 | 6 | 3-14 | 9 |

| 6×19 | 6 | 15-26 | 12 |

| 6×37 | 6 | 27-49 | 18 |

| 6×61 | 6 | 50-74 | 24 |

| 6×91 | 6 | 75-109 | 30 |

| 7×19 | 7 | 15-26 | 12 |

| 7×37 | 7 | 27-49 | 18 |

| 8×7 | 8 | 3-14 | 9 |

| 8×19 | 8 | 15-26 | 12 |

| 8×37 | 8 | 27-49 | 18 |

| 8×61 | 8 | 50-74 | 24 |

Plastic coated stainless steel wire rope material nomenclature also defines the following:

Rope Description

- length

- size (diameter)

- Preformed (pref) or non-preformed (non-Pref)

- direction and type of lay

- finish

- grade of rope

- type of core

PVC is a low cost, general purpose coating and regularly used to cover 1X19, 7X7 and 7X19 stainless steel wire rope. PVC is a very flexible coating. Typical applications include:

- Guardrail

- Catenary systems

- Washing lines

- Abattoir wire

- Security cables

- Lock cable systems

- Barrier ropes

This material is often chosen for its resistance to corrosion and chemical leaching, it has a resilience against most forms of physical damage, including impact and freezing. Typical applications include:

- Gymnasium cables

- Guardrail

- Catenary systems

- Horticultural applications

- Security cables

- Lock cable systems

- Barrier ropes

Nylon 11 and Nylon 12 is a flexible, hard-wearing and abrasion-resistant coating. A superior Ideal for running applications requiring a covered wire rope. Typical applications include:

- Cannery lines

- Gymnasium cables

- Security cables

- Roller shutter cables

- Lock cable systems

- Barrier ropes

Reviews

There are no reviews yet.