GENERAL NOTIONS OF LIFTING WIRE ROPES

| Description | Notes |

|---|---|

| Standard | For Europe, manufacturing standard for lifting wire ropes is EN 12385-4 |

| Diameter | În Europe, it is usually expressed in millimetres (mm); inch (″) values are accepted too (1 inch = 25.4 mm) |

| Length L | Usually, the length is expressed in metric values (meters, centimetres, millimetres); american unit like feet (ft) is accepted (1 ft = 0,3048 m) |

Working Load WLL | The maximum working load at which a wire rope processed by swaging, hand-splicing or other operation may be used shall be determined by the manufacturer and expressed in tonnes (t) |

Minimum Breaking Load MBL | Minimum load (force) to which the wire rope must withstand breakage, expressed in tonnes (t) or kilonewton (kN) |

Minimum Breaking Force MBF or Fmin | It is directly proportional to the square of the diameter of the wire rope, the strength class of the wire and a load coefficient, which differs depending on the construction of the wire rope |

| Safety Factor | For general purpose lifting wire ropes, the safety factor is 5; there are specific applications (mining industry, persons elevators, bridges, etc.) where wire ropes with safety-factor 6, 7 or 8 are used |

Tensile Class Rr

The steel wire resistance classes used in international standards are as follows:

- 1570 N/mm or

PS(160 kg/mm); - 1770 N/mm or

IPS(180 kg/mm); - 1960 N/mm or

EIPS(200 kg/mm); - 2160 N/mm or

EEIPS(220 kg/mm).

Higher resistance class means a higher minimum breaking load (MBL), for the same diameter.

Protective Coating of Surface

Depending on the type of protective coating used for surface, wire ropes can be:

- matte or uncoated (without surface protection);

- uncoated greased (uncoated and covered with grease);

- coated or galvanised (covered with a protective layer made from zinc alloy);

- galvanised and greased;

- made from stainless steel alloy (AISI 316, AISI 304, etc.)

Wire Rope Identification Example

Diameter 22 mm, 6x36WS-IWRC, 1960 N/mm , sZ, uncoated greased:

- 22 mm – diameter, measured with a calliper;

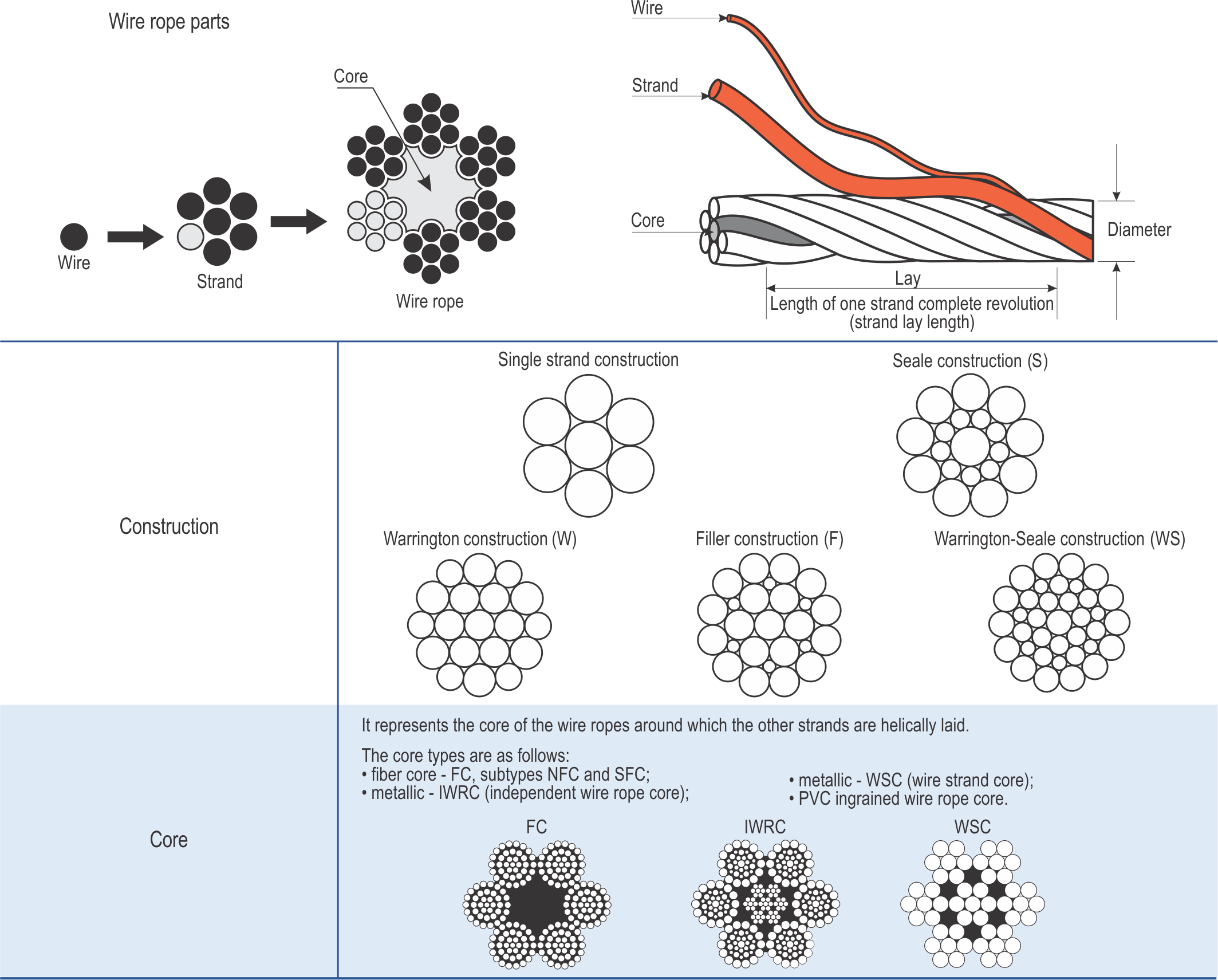

6x36WS– construction (6 strands of 36 wires, arranged Warrington Seale);IWRC– metallic independent wire rope core;- 1960 N/mm – tensile class;

sZ– type and and winding (cross right winding);- uncoated greased – surface (outer wires) covered only with grease.

The first letter indicates the direction of rotation of the strand, the second letter indicates the direction of the wire rope. As alternative notations (abbreviations), other names can be found:

- right wire rope, cross winding

(sZ): right hand, ordinary layRHO(L) - right wire rope, parallel winding

(zZ): right hand, lang’s layRHL(L) - left wire rope, cross winding

(zS): left hand, ordinary layLHO(L) - left wire rope, parallel winding

(sS): left hand, lang’s layLHL(L)

WIRE ROPE ON DRUMS

The proper measurement of the wire rope diameter

It is made always using an accurate instrument (slide ruler, calliper, etc.) by moving it and finally fitting it on the wire rope circumference.

It is made always using an accurate instrument (slide ruler, calliper, etc.) by moving it and finally fitting it on the wire rope circumference.

Measurement must be carried out on the wire rope circumference’s outer limits.

Diameter measurement is a crucial step for the correct identification of a wire rope, along with the visual examination in the section.

Proper wire rope unreeling and winding

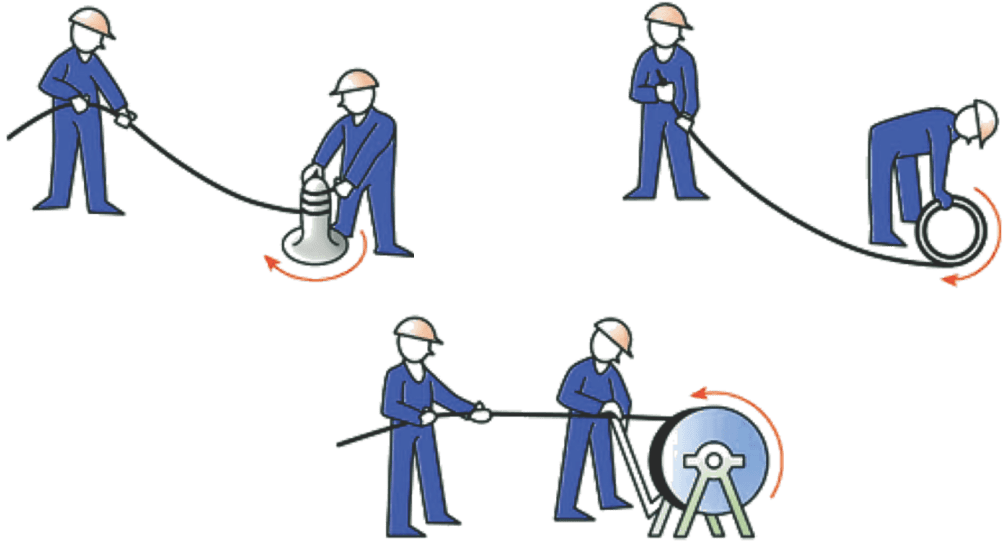

Wire rope tends to kink during uncoiling or unreeling, especially if it has been in service for a long time. In order to unreeling the wire rope is to run a steel pipe or strong rod through the center and mount the reel on drum jacks or other supports so the reel is off the ground. In this way, the reel will turn as the rope is unwound, and the rotation of the reel will help keep the rope straight.

During unreeling, pull the rope straight forward and avoid hurrying the operation. As a safeguard against kinking, never unreel wire rope from a stationary reel.

To uncoil a small coil of wire rope, simply stand the coil on edge and roll it along the ground. Never uncoil it by pulling on the end because such practice can kink or twist the rope.

How do we determine the length of rope required to wrap on a drum if we know the dimensions of the drum?

The load on the wire rope depending on the opening angle

The greater the angle formed between the arms of a wire rope lifting system, the more resistant (or thicker) wire rope is required to lift the same load.

To rewind wire rope back onto a reel or a drum, remember that it tends to roll in the direction opposite the lay.

Wire rope status depending on the sling-to-load angle

The closer the position of the wire rope to the vertical, the safer it will be operated in safer conditions and with a longer lifespan, tension inside being distributed much more evenly between the strands and wires.

Non Rotating Properties

Non Rotating Properties

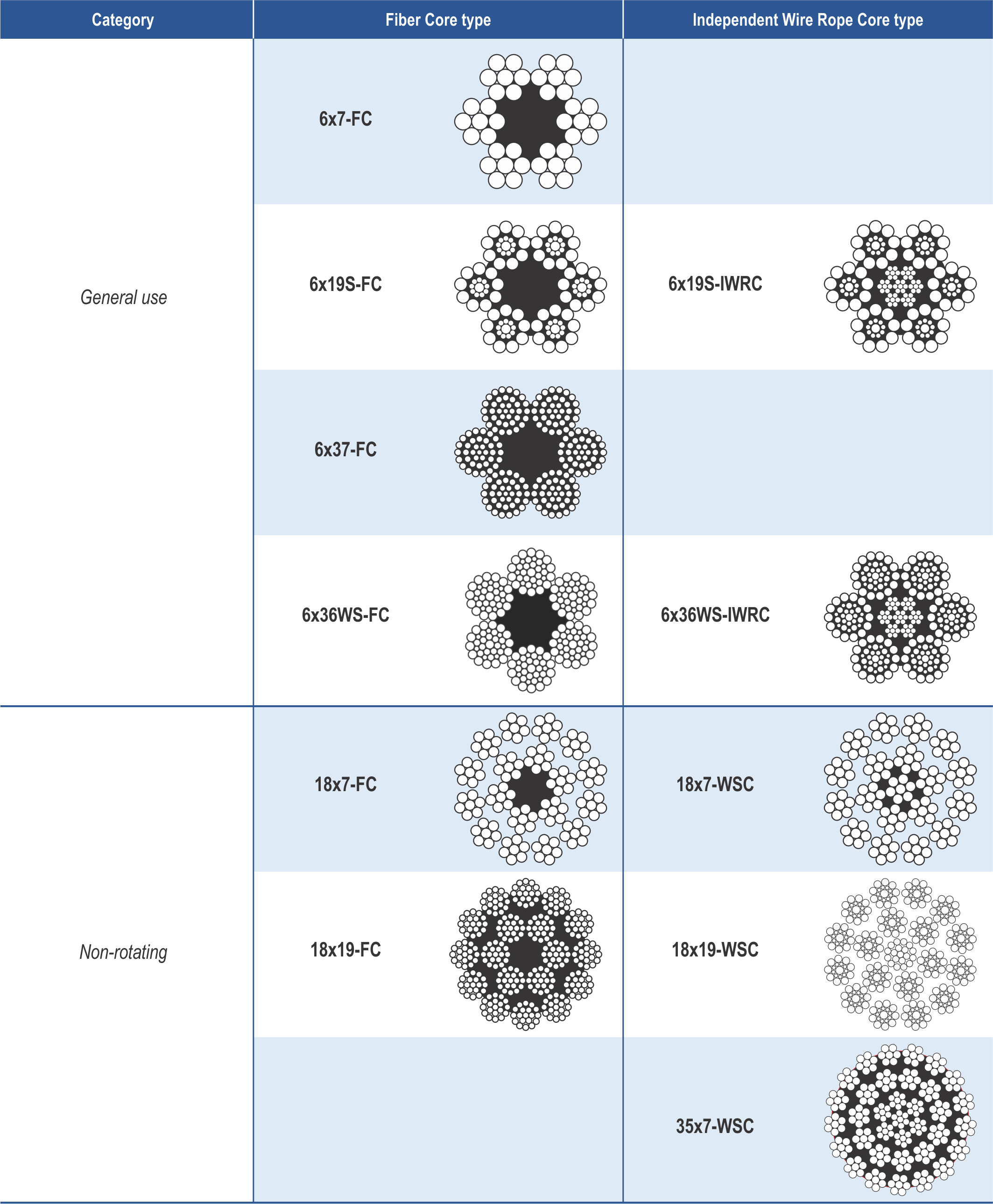

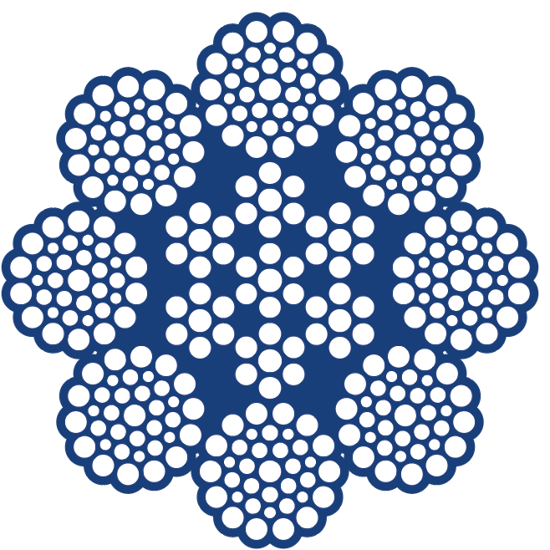

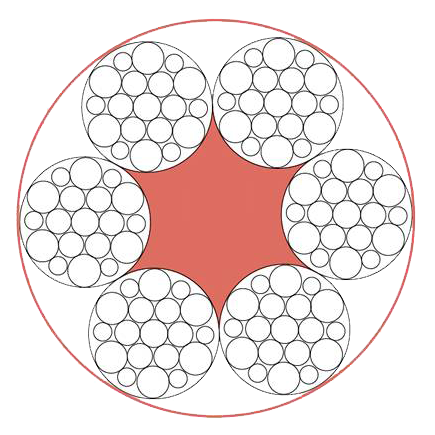

Non-rotating wire ropes have strands twisted around the core and the lay direction for outer strands is opposite to immediately inner strands. The outer rotational force of the rope will counteract the rotational force of the inner strands, leaving a wire rope that is resistant to rotating.

They have a long flexibility and lifespan, thanks to the winding of wires and strands in such a way that they generate low values for torsion time and tension when subjected to a load.

Winding the wire rope on a drum

În order to prolong lifespan of a wire rope and to avoid accidents, it is very important that the winding of a wire rope onto a drum to be done properly and to observe and respect “the hand rule”.

CHOOSE PROPER LIFTING WIRE ROPE

We sell and deliver from stock high-load wire ropes in different constructions and diameters, for various lifting applications.

We supply, on request, various constructions, both for general lifting applications and specific wire ropes.

These wire ropes can be terminated with wire clips, resin fixed and swaged sockets, mounted on the drum of the equipments or can be braided.

We are also available with various other cable constructions – from classes 2160, 1960 or older 1770 N/mm2.

The most common constructions provided are shown in the table below:

Non Rotating Properties

Non Rotating Properties