Supply Stainless Steel Wire Rope 7×19/7×7 construction Best factory from China

Wire rope

Wire rope is a collection of small strands of wire woven together in three different patterns which offer different levels of flexibility. Stainless steel rope can be used for the most demanding rigging applications, and comes in various constructions.

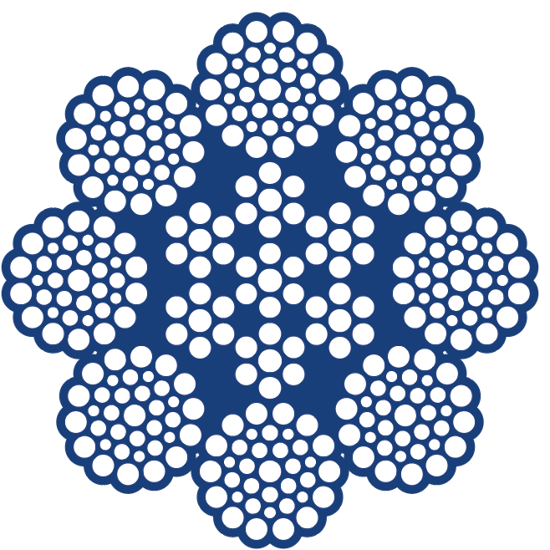

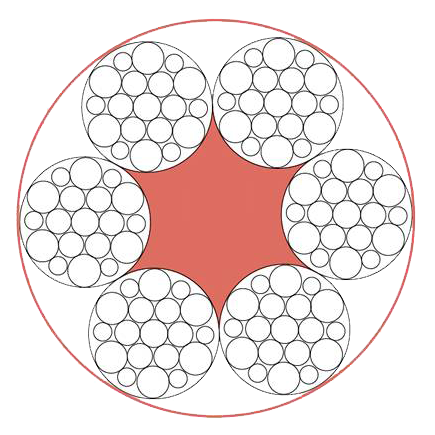

- 7 x 19 Stainless Steel Wire Rope consists of 7 strands each with 19 wires. It is the most common and versatile construction, and is flexible and easy to work with when the rope needs to turn corners or change direction. Commonly use is with a thimble and swage for fixed rigging applications. 7 x 19 is also used for limited working rope applications such as on a boat winch.

- 7 x 7 Stainless Steel Wire Rope consists of 7 strands each with 7 wires. It is not as flexible as 7 x 19, but can be wrapped around a thimble in smaller sizes. 7 x 7 is ideal for fixed rigging applications that require a slight angle, such as balustrading and safety barrier rail.

- 1 x 19 Stainless Steel Wire Rope consists of a single strand with 19 wires. It has a high breaking load and low stretch characteristics, but is the least flexible construction, and will not bend around corners or angles. 1 x 19 is suitable for fixed “straight line” rigging applications only, such as mast stays, guy ropes and structural applications. It is best utilised with machine swagged end fittings.

7×7 AISI316 stainless steel wire rope is used for a wide range of applications. More flexible than 1×19 but more rigid than 7×19, the 7×7 construction is often used where 1×19 lacks enough flexibility for an application or where 7×19’s weaker breaking load is too low for an application. Used extensively throughout the marine industry as well as for general engineering applications, 7×7’s excellent breaking load and flexibility in the smaller diameters make it a favourite for control cable and a variety of marine rigging applications, examples of which are shown below:

- Applications

- Control cables

- Guardrail

- Standing rigging

- Running rigging

- Steering cable

- Marine/Saltwater environment

- Sewage treatment works

- Wire rope slings

- Davit ropes

| Breaking Loads | |||

|---|---|---|---|

| Nominal Diameter | Approximate Mass | Minimum breaking loads – 1570 Mpa | |

| [mm] | [kg/m] | [kN] | [Kg] |

| 1 | 0.004 | 0.59 | 60 |

| 2.0 | 0.016 | 2.37 | 241 |

| 2.5 | 0.023 | 3.71 | 378 |

| 3.0 | 0.034 | 5.34 | 544 |

| 4.0 | 0.060 | 9.49 | 967 |

| 5.0 | 0.095 | 14.80 | 1,509 |

| 6.0 | 0.136 | 21.40 | 2,182 |

| 7.0 | 0.185 | 29.10 | 2,967 |

| 8.0 | 0.242 | 38.00 | 3,874 |

| 10.0 | 0.378 | 59.30 | 6,046 |

| 12.0 | 0.545 | 85.40 | 8,708 |

| 14.0 | 0.741 | 117.00 | 11,930 |

Stainless steel wire ropes boast higher corrosion resistance to salt water than galvanized wire ropes, so they are the best choice of marine applications. Meanwhile, the bright appearance of galvanized wire ropes will dull over time, but stainless steel wire rope will maintain its bright and modern appearance for years. Therefore they are generally used in decoration for modern display and architectural purposes, such as railings, architectural cables, cable balustrades, handrails, etc.

Stainless steel wire rope

Stainless steel wire rope

Normally, stainless steel wire rope is made of 304, 305 or 316. And here is a simple comparison of these materials:

- The 304 material, as the most common type, is magnetic with excellent corrosion resistance and strength compared with galvanized steel wire ropes. But it still will corrode to some extent over year so it is not suitable for marine and food applications.

- The 305 material is more corrosive resistant than 304. Meanwhile, it is largely non-magnetic perfectly suited for aeronautical and naval fields.

- The 316 materials is the most corrosive resistant type and highly used in high corrosion environments and places with high salt spray. But the 316 material is about 10% less strength than 304 stainless steel.

Construction:

Four main constructions of stainless steel wire ropes – 1 × 19, 7 × 7, 7 × 19, 6 × 36 FC/IWRC are available

Reviews

There are no reviews yet.