CRANE WIRE ROPE – LONG-LASTING, ROBUST AND SAFE

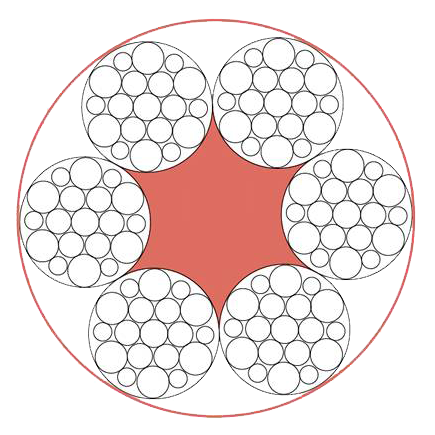

Crane wire rope form an important link in the world’s economy. The offshore, logistics and construction industries are but three industries with ever-increasing demands on the quality of our high-performance ropes. Not only do they have to withstand extreme weather conditions and frequent load changes, but it must also be ensured that downtimes for maintenance and replacement are kept to a minimum. Our crane ropes are designed to meet exactly these requirements. LKS Wire Ropes provides you with an extensive range of ropes for all common crane applications. These include both rotation-resistant and non-rotation-resistant designs. Depending on your requirements, we offer ropes which are compacted using a variety of methods, and with various degrees of compaction. Additional plastic padding improves the shape stability of the rope and prevents premature wear from appearing in the interior of the rope.

Non-rotation-resistant ropes should be used in pairs in order for their respective physically implemented rotation behaviours to cancel each other out.

EN 12385-3 defines rotation resistance and describes all ropes with rotation properties of more than 4 rotations/1,000 d under a load of 20% of the minimum breaking force. Swivels should not be used.You can also find the steel wire rope weight on the below table.

| Rope Nominal Diameter (mm) |

Approx. Weight (kg/100m) |

Nominal Tensile Strength(MPa) | |||||||||||||

| 1570 | 1670 | 1770 | 1870 | 1960 | 2160 | ||||||||||

| Natural Fiber Core | Synthetic Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | Fiber Core | Steel Core | |

| 16 | 91.4 | 88.1 | 111 | 118 | 139 | 125 | 148 | 133 | 157 | 140 | 166 | 147 | 174 | 162 | 191 |

| 18 | 116 | 111 | 141 | 149 | 176 | 159 | 187 | 168 | 198 | 178 | 210 | 186 | 220 | 205 | 242 |

| 20 | 143 | 138 | 174 | 184 | 217 | 196 | 231 | 207 | 245 | 219 | 259 | 230 | 271 | 253 | 299 |

| 22 | 173 | 166 | 211 | 223 | 263 | 237 | 280 | 251 | 296 | 265 | 313 | 278 | 328 | 306 | 362 |

| 24 | 206 | 198 | 251 | 265 | 313 | 282 | 333 | 299 | 353 | 316 | 373 | 331 | 391 | 365 | 430 |

| 26 | 241 | 233 | 294 | 311 | 367 | 331 | 391 | 351 | 414 | 370 | 437 | 388 | 458 | 428 | 505 |

| 28 | 280 | 270 | 341 | 361 | 426 | 384 | 453 | 407 | 480 | 430 | 507 | 450 | 532 | 496 | 586 |

| 30 | 321 | 310 | 392 | 414 | 489 | 440 | 520 | 467 | 551 | 493 | 582 | 517 | 610 | 570 | 673 |

| 32 | 366 | 352 | 445 | 471 | 556 | 501 | 592 | 531 | 627 | 561 | 663 | 588 | 694 | 648 | 765 |

| 34 | 413 | 398 | 503 | 532 | 628 | 566 | 668 | 600 | 708 | 633 | 748 | 664 | 784 | 732 | 864 |

| 36 | 463 | 446 | 564 | 596 | 704 | 634 | 749 | 672 | 794 | 710 | 839 | 744 | 879 | 820 | 969 |

| 38 | 516 | 497 | 628 | 664 | 784 | 707 | 834 | 749 | 884 | 791 | 934 | 829 | 979 | 914 | 1080 |

| 40 | 571 | 550 | 696 | 736 | 869 | 783 | 925 | 830 | 980 | 877 | 1040 | 919 | 1090 | 1010 | 1230 |

| 42 | 630 | 607 | 767 | 811 | 958 | 863 | 1020 | 915 | 1080 | 967 | 1140 | 1010 | 1200 | 1120 | 1320 |

| 44 | 691 | 666 | 842 | 890 | 1050 | 947 | 1120 | 1000 | 1190 | 1060 | 1250 | 1110 | 1310 | 1230 | 1450 |

| 46 | 755 | 728 | 920 | 973 | 1150 | 1040 | 1220 | 1100 | 1300 | 1160 | 1370 | 1220 | 1430 | 1340 | 1580 |

| 48 | 823 | 793 | 1000 | 1060 | 1250 | 1130 | 1330 | 1190 | 1410 | 1260 | 1490 | 1320 | 1560 | 1460 | 1720 |

| 50 | 892 | 860 | 1090 | 1150 | 1360 | 1220 | 1440 | 1300 | 1530 | 1370 | 1620 | 1440 | 1700 | 1580 | 1870 |

| 52 | 965 | 930 | 1180 | 1240 | 1470 | 1320 | 1560 | 1400 | 1660 | 1480 | 1750 | 1550 | 1830 | 1710 | 2020 |

| 54 | 1040 | 1000 | 1270 | 1340 | 1580 | 1430 | 1680 | 1510 | 1790 | 1600 | 1890 | 1670 | 1980 | 1850 | 2180 |

| 56 | 1120 | 1080 | 1360 | 1440 | 1700 | 1530 | 1810 | 1630 | 1920 | 1720 | 2030 | 1800 | 2130 | 1980 | 2340 |

| 58 | 1200 | 1160 | 1460 | 1550 | 1830 | 1650 | 1940 | 1740 | 2060 | 1840 | 2180 | 1930 | 2280 | 2130 | 2510 |

| 60 | 1290 | 1240 | 1570 | 1660 | 1960 | 1760 | 2080 | 1870 | 2200 | 1970 | 2330 | 2070 | 2440 | 2280 | 2690 |

Note: Steel wire min. aggregate breaking strength = Min. breaking strength of steel wire rope x 1.226 (Fiber core) or 1.374(steel core).

Steel wire rope tensile strength

The basic material is wire rod, which is cold-drawn into wire of different diameters and steel wire rope tensile strength grades.

The most common grades are:

|

Rope grade

|

Wire tensile strength grades

|

Hardness app.

|

|||||

|

EN

|

API 9A

|

Min

|

Max

|

Brinel

|

Rockwell

|

||

|

kp/mm²

|

N/mm²

|

kp/mm²

|

N/mm²

|

HB

|

HRC

|

||

|

1570

|

PS

|

140

|

1370

|

180

|

1770

|

405/425

|

45

|

|

1770

|

IPS

|

160

|

1570

|

200

|

1960

|

445/470

|

49

|

|

1960

|

EIPS (XIP)

|

180

|

1770

|

220

|

2160

|

470/480

|

51

|

|

2160

|

EEIPS (XXIP)

|

200

|

1960

|

220

|

2160

|

480/500

|

52

|

According to the price per ton of wire rope, the finer the wire rope is, the more expensive it is, the more complex the treatment process is, and the greater the unit cost is. According to the price of rice, the thicker the month is, the heavier the weight is. In fact, it’s the same by ton and meter. It’s suggested that customers purchase by meter, which is convenient for cost accounting.

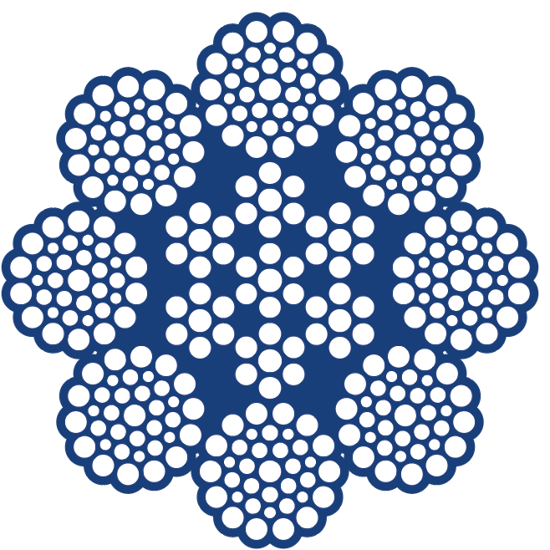

High standard wire rope standard: 1. Raw material: 70 steel, 72A, 82B; 2. Heat treatment process: lead bath heat treatment; 3. Twisting: front deformation, back deformation, online pre tension; 4. Rope core: pure hemp core, jute, sisal; 5. Package: high quality wooden plate and iron plate; 6. Structure: 6 * 19W, 6 * 19S.

Standard of common standard wire rope: 1. Raw material: 45 steel, 60 steel, 65 steel; 2. Heat treatment process: normalizing heat treatment; 3. Twisting: front deformation, back deformation, no on-line pretension; 4. Rope core: yarn core, cotton core; 5. Packaging: ordinary wooden plate, recycled wooden plate; 6. Structure: 6 * 19,6 * 37.

The price of galvanized steel wire rope of the same specification is 1000-1500 yuan / ton higher than that of ungalvanized steel wire rope, while that of hot-dip galvanized steel wire rope is 2000-3000 yuan / ton higher than that of ungalvanized steel wire rope.

Steel wire rope weight calculator

| Item | Rope construction | Weight factor K(kg/100m·mm) | K2/K1n | K2/K1p | Minimum breaking strength factor K’ | K’1/K’2 | |||

| Natural fiber core | Synthetic fiber core | Steel core | Fiber core | Steel core | |||||

| K1n | K1p | K2 | K’1 | K’2 | |||||

| 2 | 6X7 | 0.351 | 0.344 | 0.387 | 1.1 | 1.12 | 0.332 | 0.359 | 1.08 |

| 3 | 6X19(a) | 0.38 | 0.371 | 0.418 | 1.1 | 1.13 | 0.33 | 0.356 | 1.08 |

| 4 | 6X37(a) | ||||||||

| 3 | 6X19(b) | 0.351 | 0.344 | 0.4 | 1.14 | 1.16 | 0.307 | 0.332 | 1.08 |

| 4 | 6X37(b) | 0.346 | 0.337 | 0.4 | 1.16 | 1.19 | 0.295 | 0.319 | 1.08 |

| 5 | 6X61 | 0.361 | 0.354 | 0.398 | 1.1 | 1.12 | 0.283 | 0.306 | 1.08 |

| 6 | 8X19 | 0.357 | 0.344 | 0.435 | 1.22 | 1.26 | 0.293 | 0.346 | 1.18 |

| 7 | 8X37 | ||||||||

| 8 | 18X7 | 0.39 | 0.43 | 1.1 | 1.1 | 0.31 | 0.328 | 1.06 | |

| 9 | 18X19 | ||||||||

| 10 | 34X7 | 0.39 | 0.43 | 1.1 | 1.1 | 0.308 | 0.318 | 1.03 | |

| 11 | 35WX7 | — | 0.46 | — | — | — | 0.36 | — | |

| 12 | 6X12 | 0.251 | 0.231 | — | — | — | 0.209 | — | — |

| 13 | 6X24 | 0.318 | 0.304 | — | — | — | 0.28 | — | — |

Note1: in item 3 and item 6, the weight factor will be 3% less than the factor in the table when wire quantity is 19 or much less.

Note2: in item 13, the weight factor and minimum breaking strength factor of equidistant twisted length wire rope should be 4% greater than the factor in table.

Note 3: K1p is the weight factor for wire rope with polypropylene core.

Reviews

There are no reviews yet.