PLASTIC PADDING

PLASTIC PADDING

The plastic padding supports the strands and stabilises the rope structure. The plastic encasings the lubricated steel core and thus provides double protection. On the one hand, it encloses the lubricant on the inside and, on the other hand, it simultaneously keeps humidity and dirt particles away from the core. Furthermore, the plastic padding prevents direct friction between the strands in the rope and thus also helps to prevent premature wear. In addition, the rope structure is stabilised by the layer of plastic.

|

ADVANTAGES

• Counteracts interior wire breaks

• Preserves the lubrication on the steel core

• Protects the core from humidity and dirt particles

• Minimises friction losses

• Improves shape stability

• Absorbs vibrations

PLASTIC COATING

As an additional added value, we can coat our ropes with various common types of plastic on modern extrusion equipment. The following materials, among others, are processed: PVC, LDPE, HDPE, PP, PA 6, PA 6.12, PA 11, PA 12, PUR TPU and POM. These plastics can be laid around the rope in various processes, depending on the customer requirement and further use of the product.

Hose process:

Simple coating, e.g., when the end fittings are later applied to the rope.

Pressure process:

Very smooth, high-quality surface on the final coated product; very good connection between the coating and the rope.

Semi-process:

Smoother surface than with the hose process but, depending on the rope construction, easier to strip than a coating in the pressure process.

By adding colour granules, almost any colour setting is possible. Furthermore, the technical properties of the coating, e.g., friction values, can also be positively influenced with the appropriate additives. Here, too, we will gladly place our know-how at your disposal.

Plastic Coated

Various wire rope constructions are available with a plastic coating applied to the exterior of the rope. Small diameter galvanized and stainless steel wire ropes with plastic coating are common. The plastic coating can provide protection against corrosion and in some cases reduce wear of the rope and other rigging components. Plastic coated ropes can be difficult to inspect. Nominal strengths for plastic coated ropes are based on the diameter and grade of the rope prior to coating.

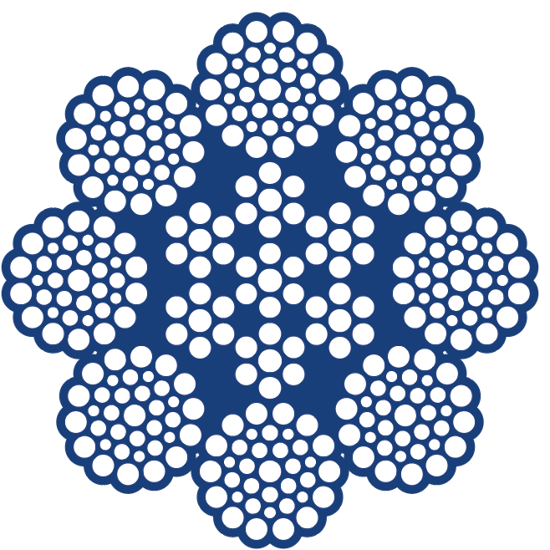

Plastic Filled

Plastic filled wire ropes are wire ropes in which internal spaces are filled with a matrix of plastic. The plastic extends to, or slightly beyond, the outer circumference of the rope. Plastic filling may improve bending fatigue life by reducing internal and external wear. Nominal strengths for plastic filled ropes are based on the diameter and grade of the rope prior to plastic filling.

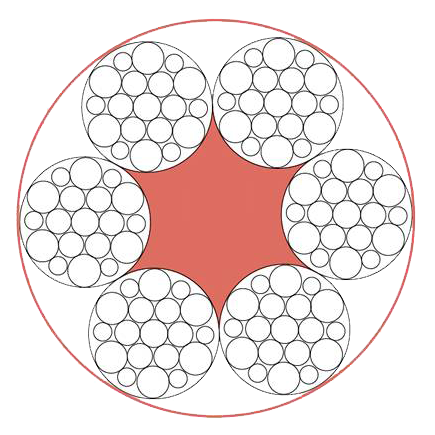

Plastic Coated IWRC

Plastic coated IWRC wire rope is wire rope which incorporates a plastic coated or plastic filled IWRC. The plastic coated or plastic filled IWRC reduces internal wear and may increase bending fatigue life. Nominal strengths for plastic coated and plastic filled ropes are based on the diameter and grade of the rope with an uncoated or unfilled IWRC.

No comment