| Nominal

Rope Diameter |

Approx. weight/mass. | Minimum breaking load/force

FOR 1570 OR 1370 / 1770 N/mm2 |

|||

|---|---|---|---|---|---|

| inch | mm | Ibs/100ft | kg/100m | 1000 Ibs | kN |

| 1/4 | 6 | 8.4 | 12.5 | 4.0 | 17.8 |

| 6.5 | 10.3 | 15.3 | 5.0 | 22.4 | |

| 5/16 | 8 | 14.9 | 22.1 | 7.1 | 31.7 |

| 9 | 19.6 | 29.2 | 9.0 | 40.2 | |

| 10 | 23.7 | 35.2 | 11.1 | 49.5 | |

| 7/16 | 11 | 28.6 | 42.6 | 13.4 | 59.7 |

| 15/32 | 12 | 33.5 | 49.8 | 16.0 | 71.3 |

| 13 | 40.0 | 59.5 | 18.8 | 83.7 | |

| 9/16 | 14 | 47.7 | 71.0 | 21.8 | 97.0 |

| 5/8 | 16 | 60.5 | 90.1 | 28.6 | 127.0 |

| 3/4 | 19 | 85.3 | 127.0 | 40.2 | 179.0 |

| 22 | 114.2 | 170.0 | 54.0 | 240.0 | |

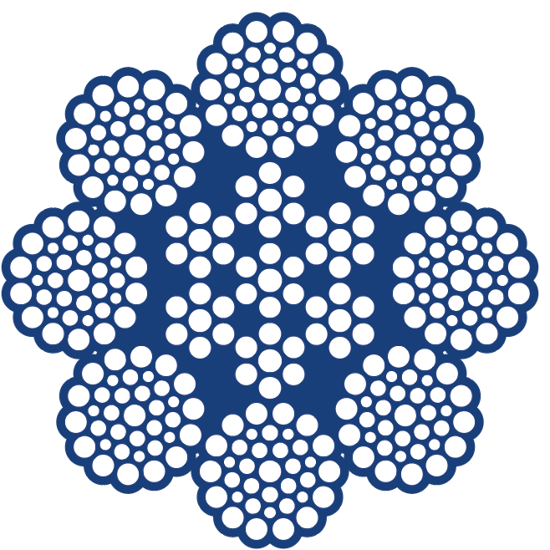

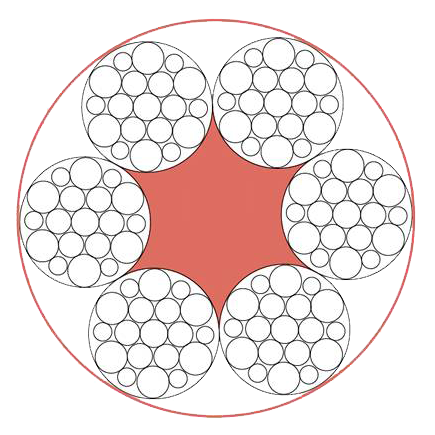

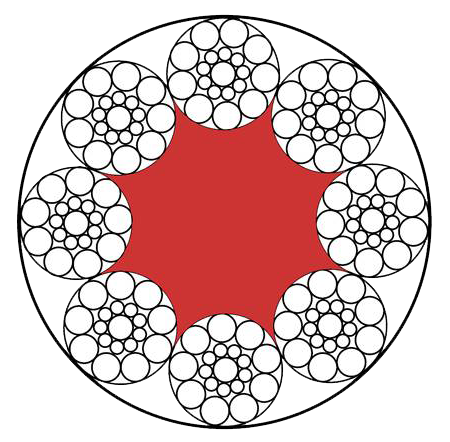

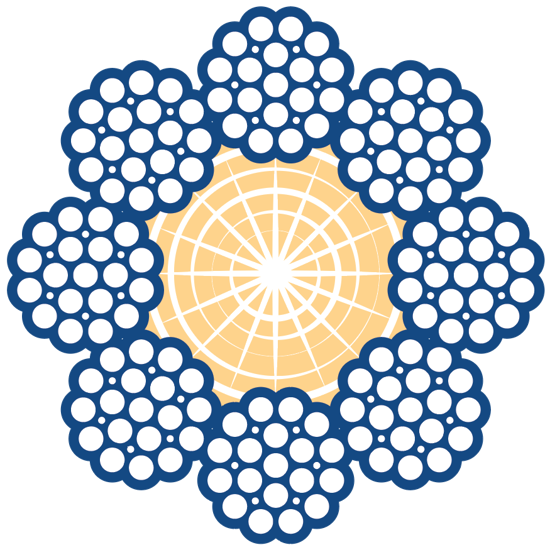

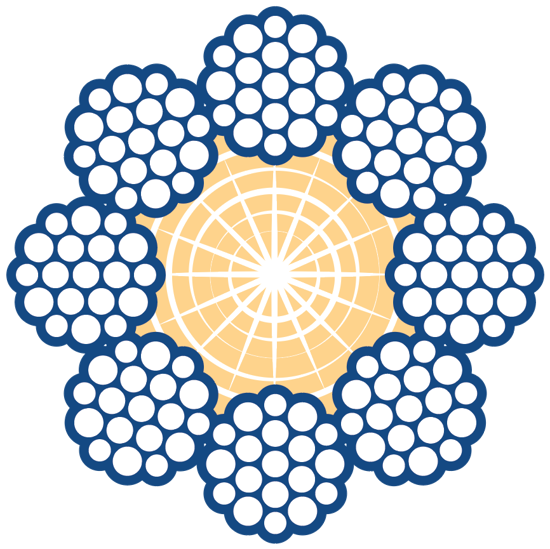

8x19W+NFC ELEVATOR WIRE ROPES

The company offers a complete range of high quality elevator ropes, ensuring superior performance and high order of safety requirements. Our products are manufactured in advanced state-of-the-art technology and undergoes strict quality control measures. Elevator ropes are designed with close dimensional tolerances to facilitate jerk free movement of elevators.

Throughout the entire manufacturing process, the ropes are closely monitored to ascertain desired tolerances are meet and diameter is consistent to ensure correct contact between the rope and groove. Routine and regular testing for fatigue endurance, elongation characteristics and diameter stability are carried out on a dedicated fatigue test facility to deliver consistent rope performance.

Our quality systems have been accredited by ISO 9001:2008 and ISO 14001:2004. The elevator ropes are designed to meet desired OEM specifications, which are available as the Hoist ropes, Compensating ropes, Governor ropes and Control ropes used in traction drive elevators and roped hydraulic lifts.

No comment