Compacted Strand Wire Rope

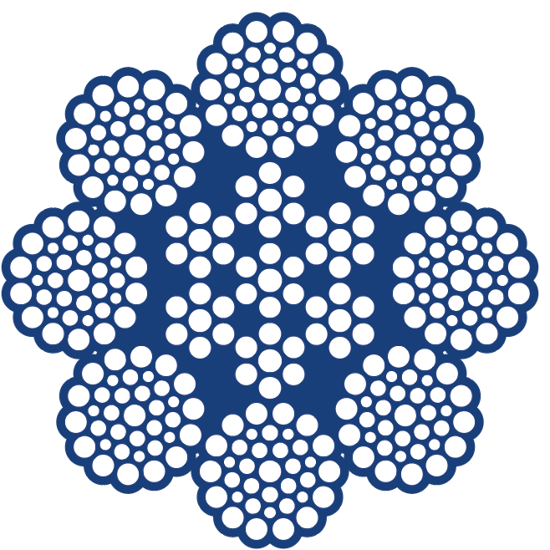

Compacted strand wire rope is a wire rope manufactured from strands which have been compacted or reduced in diameter prior to laying strands around the core into a finished wire rope. There are various known methods for compacting; drawing the strand through a compacting die, roller reduction and rotary swaging are several examples. The compacting process flattens the surface of the outer wires and reforms internal wires of the strand to increase the metallic area of the strand. The result is a smoother bearing surface at the strand crowns and an increase in nominal strength over round strand rope of the same diameter and classification.

Compacted Strand Rope Cross-sections

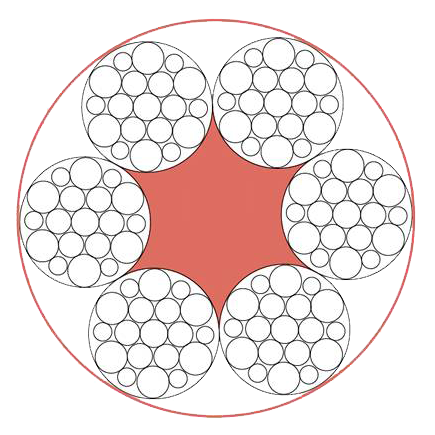

The entire cross section of a rope is compacted or reduced in diameter following laying strands around the IWRC to produce compacted or swaged wire rope. Rotary swaging is the most common process for compacted rope although other processes may be used. As illustrated the wires and strands of the rope are flattened to produce a relatively smooth and wear resistant outer surface. Compacted rope generally has good wear resistance, crushing resistance and high strength, however bending fatigue life may be reduced by the compacting process.

COMPACTION

To increase the breaking force of our products without increasing the diameter of the rope, we compact the strands, the rope or both in combination. In addition to the greater metal cross section and the resulting higher breaking force, compacted ropes also have smoother strand and rope surfaces.

Compacted strands provide the rope with greater flexibility and minimise both friction and corrosion in the rope. In addition, they reduce the risk of negative imprints in the grooves of the rollers and improve the service life of the rope in the casing of multi-layer winding.

Furthermore, the compaction of the rope increases its pressure stability and, due to a lower tendency to indent and optimised pressure distribution, it improves the properties of the rope for multi-layer winding.

ADVANTAGES

• Increases the metallic cross section and the breaking forces

• Increases the surface contact between individual wires

• Achieves a smoother rope surface

• Improves the contact ratio between the rope and the rope groove

• Reduces the indenting of adjacent rope strands

• Improves the structure stability in the casing of multi-layer windings

Non-compacted |

Compacted |

No comment