6×31 Warrington Seale construction is a good general purpose wire rope that is wear and crush resistant, but not very flexible. Suitable for trolley ropes, slusher ropes and hoist ropes.The larger outer wires increases the wearability and abrasion resistance versus other constructions of similar strength.

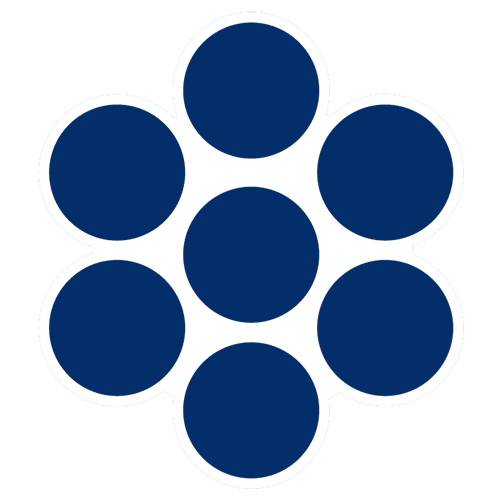

A 6X19 class wire rope contains 6 strands with 16 through 26 wires per strand. Our 6×19 class typically has either 19 (6X19) or 26 (6X26) wires per strand. It is a general purpose rope most commonly used for wire rope chokers and other rigging. 6X19 and 6X26 offer great abrasion resistance and crush resistance when spooling.

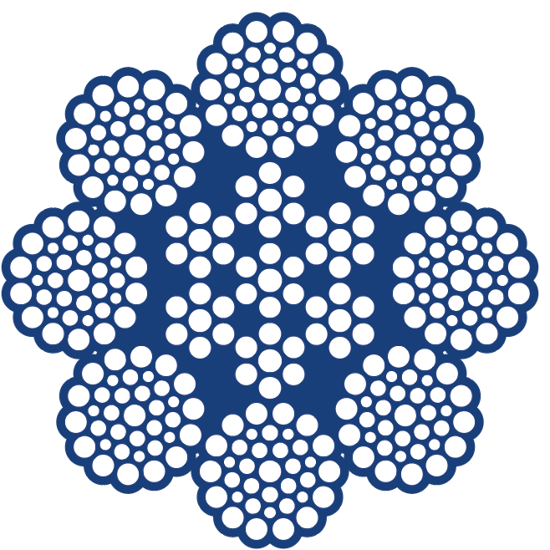

A 6X37 class wire rope contains 6 strands with 27 through 49 wires per strand. Our 6X37 typically has 36 wires per strand. It is a general purpose wire rope with excellent flexibility for spooling. With the smaller wires per strand, the trade off for excellent flexibility is reduced abrasion resistance.

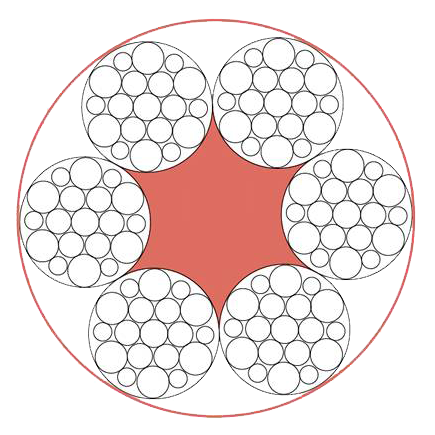

IWRC (Independent Wire Rope Core) wire ropes offer more crush resistance when spooling while FC (Fiber Core) wire ropes offer more flexibility. FC wire ropes are not as crush resistant when spooling compared to an IWRC wire rope.

No comment