Whether it is surface or underground mining, our company will always have optimal wire ropes products when and where you need them most. With advanced design, our mining wire ropes are capable to withstand the harshest working environments. Meanwhile, they boast the following incomparable benefits:

- High tensile strength and breaking load.

- High quality steel wire for enhanced wear resistance.

- Excellent ductility for optimal fatigue properties on rope level.

- Longer service life regardless of rugged environments.

- Offering better level of safety and productivity.

- Suitable for mining with higher depth.

- Lower cost per ton.

- Tough hoist and lifting wire rope.

- Dragline.

- Ancillary lines.

- Deep-shaft mining.

- Haulage ropes.

- Shovel ropes.

- Ropes for excavators

- Pendant lines.

- Retract ropes.

Advantage:

1. Accurate wire pitch

2. Compact structure

3. High breaking strength

4. Exceptional fatigue properties

5. Long life, reduced downtime costs

6. Accurate diameter for effective multi-layer spooling(Tolerance:±1%.)

7. Complete Quality Control system, Make sure the quality is the first aim in production.

8. Galvanized, Bright, Lubricated, Plastic insert, High tensile grade, Coated, Rotation rope, Non-rotation rope and so on.

Material: high tensile carbon steel 60# SHAGANG, heat treatment steel wire

| STEEL GRADE | CHEMICAL COMPOSITION(%) | ||||

| C | Si | Mn | p | S | |

| 60# | 60 | 20 | 53 | 10 | 9 |

Production Line:

Company products:

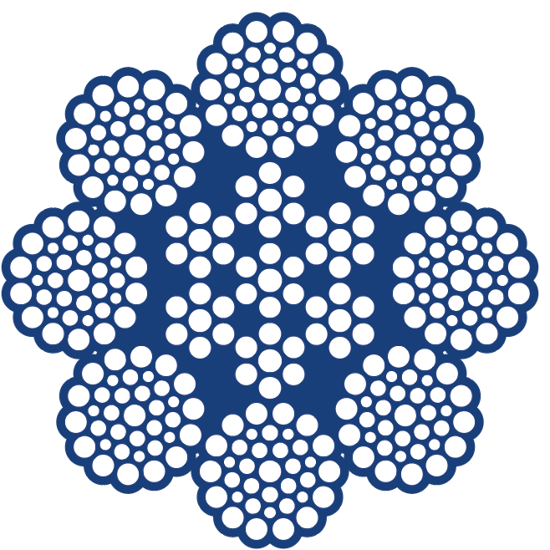

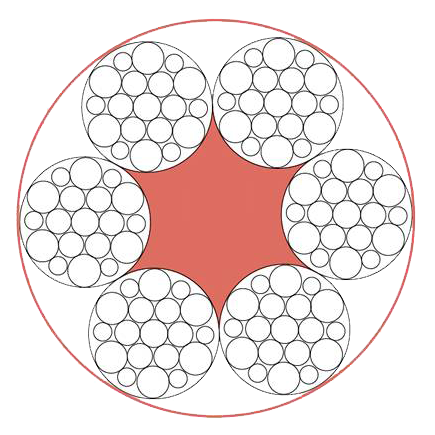

What is wire rope specifications construction?

What is wire rope specifications construction? Wire rope is a complex mechanical device that has many moving parts all working in tandem to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

Wire rope is a preferred lifting device for many reasons. Its unique design consists of multiple steel wires that form individual strands laid in a helical pattern around a core. This structure provides strength, flexibility, and the ability to handle bending stresses. Different configurations of the material, wire, and strand structure will provide different benefits for the specific lifting application, including:

- Strength

- Flexibility

- Abrasion resistance

- Crushing resistance

- Fatigue resistance

- Corrosion resistance

- Rotation resistance

However, selecting the proper wire rope for your lifting application requires some careful thought. Our goal is to help you understand the components of a wire rope, the construction of wire rope, and the different types of wire rope and what they might be used for. This will allow you to select the best performing and longest-lasting wire rope for the job at hand.

FAQ

Q: Manufacturer or Trader?

A: We are a manufacturer in the wire industry for more than 20 years.

Q: Producing Capacity?

A: The production capacity totally is 9, 000 tons per month. The production capacity of this product is 1,500 tons per month.

Q: Main Market?

A: Our main market is foreign customers. 80% of the products are for exporting. The main countries are Japan, South Korea, South Asian area, Europe, America, Canada, and South America etc.

Q: What information should I provide when inquiring?

A: The diameter before PVC coating; after PVC coating, the requirement of the core wire-like zinc coating, tensile strength, packing, color

Q: What is the MOQ?

A: For quality checking, we accept small quantity orders like one coil. For normal cooperation, we prefer FCL container quantity to ensure the safety of goods in transportation.

Q: What is the payment term?

A: T/T; L/C; D/P etc

Q: Free sample available?

A: Yes. Free sample within 1kg is available

Q: Third Party Inspection available?

A: Yes, available. The charges are on the buyer.

Reviews

There are no reviews yet.