7×19 6mm galvanized steel wire rope

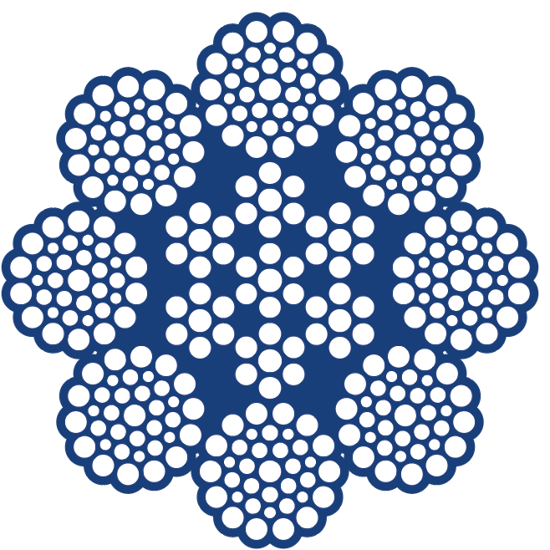

6×19 construction galvanized steel wire rope is available with either FC (fibre core) or WSC (wire strand core). When supplied with a wsc the rope is more commonly referred to as 7×19. The rope is very popular in diameters from 3mm to 16mm and is used on a variety of applications. 6×19 FC and 6×19 WSC (7×19) is very flexible in diameters 3mm to 6mm and is used for many requirements where wire ropes are running over pulleys. 7×19 construction is readily available in both galvanised and marine grade stainless steel.

- Applications

- Where cables are required to run over pulleys

- General engineering applications

- Industrial door cables

- Garage door cables

- Control cables

- Gym equipment cables

- Wire rope slings

- Wind turbine

- Whip checks

- Winch ropes

| Breaking Loads | |||

|---|---|---|---|

| Nominal Diameter | Approximate Mass | Minimum Breaking Loads | |

| 1770 Mpa | |||

| [mm] | [kg/m] | [kN] | [Kg] |

| 3 | 0.034 | 5.77 | 588 |

| 4 | 0.061 | 10.25 | 1,045 |

| 5 | 0.095 | 16.02 | 1,633 |

| 6 | 0.137 | 23.07 | 2,352 |

| 7 | 0.187 | 31.40 | 3,202 |

| 8 | 0.244 | 41.01 | 4,182 |

| 9 | 0.309 | 51.90 | 5,293 |

| 10 | 0.381 | 64.07 | 6,535 |

| 11 | 0.461 | 77.53 | 7,908 |

| 12 | 0.549 | 92.27 | 9,411 |

| 13 | 0.644 | 108.29 | 11,045 |

| 14 | 0.747 | 125.59 | 12,809 |

| 16 | 0.975 | 164.03 | 16,731 |

| 18 | 1.234 | 207.60 | 21,175 |

| 20 | 1.524 | 256.30 | 26,142 |

In ordering steel wire rope, you are requested to give us complete information as specified below:

a. Purpose: For which rope will be used.

b. Size: Diameter of the rope in millimeter or inches

c. Construction: Number of strands, number of wires per strand and type of strand construction.

d. Type of Core: Fiber core( FC), independent wire rope core(IWRC) or independent wire strand core(IWSC).

e. Lay: Right regular lay, left regular lay, right lang lay, left lang lay.

f. Coating: Bright(ungalvanized), galvanized or stainless, PVC or Grease.

g. Grade of wire: Tensile strength of wires.

h. Breaking Load: Minimum or calculated breaking load in tones or pounds.

i. Lubrication: Whether lubrication is desired or not, and required lubricant.

j. Length: Length of wire rope.

k. Packing: In coils wrapped with oil paper and hessian(orp.p) cloth, or on wooden reels.

l. Quantity: By number of coils or reels, by length or weight.

m. Remarks: Shipping marks and any other special requirement.

If you are going to pick up steel wire ropes that suit your project perfectly, you must have an ideal about the construction about them. Our company can supply bright wire rope, galvanized wire rope, stainless steel wire rope, compacted wire rope, rotation resistant wire ropes, mining wire rope, elevator wire rope, crane wire rope and gas & oilfield wire ropes. Here are some details to solve the problem that may puzzle you whether you are browsing the web or picking up steel wire ropes.

Bright, Galvanized or Stainless steel?

- Bright steel wire ropes mean no surface treatment is applied to the rope. Therefore, they have the lower price among these three wire ropes. Generally, they are fully lubricated to protect the rope from rust and corrosion.

- Galvanized steel wire ropes feature compressed zinc coating for providing excellent corrosion resistance. With higher break strength yet lower price than stainless steel, galvanized steel wire ropes are widely used in general engineering applications such as winches and security ropes.

- Stainless steel wire ropes, made of quality 304, 305, 316 steels, are the most corrosive type for marine environments and other places subjected to salt water spray. Meanwhile, bright and shiny appearance can be maintained for years rather than dull as galvanized steel wire ropes.

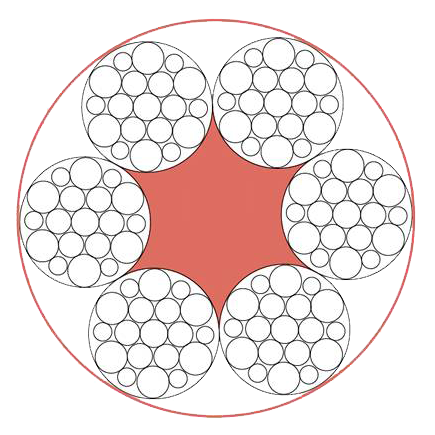

FC, WSC or IWRC?

FC stands for fiber core, made of natural or synthetic fiber, which can provide excellent flexibility and resistance to contact pressure. The fiber core can store lubrication to reduce the friction between wire strands effectively. Meanwhile, the fiber core makes the rope lower deformable with low elastic rope elongation.

FC stands for fiber core, made of natural or synthetic fiber, which can provide excellent flexibility and resistance to contact pressure. The fiber core can store lubrication to reduce the friction between wire strands effectively. Meanwhile, the fiber core makes the rope lower deformable with low elastic rope elongation. WSC is abbreviation of wire strand core. WSC ropes features better heat resistance than FC ropes, meanwhile, increase metallic section provide added 15% of strength. However, WSC steel ropes are less flexible than those with fiber cores.

WSC is abbreviation of wire strand core. WSC ropes features better heat resistance than FC ropes, meanwhile, increase metallic section provide added 15% of strength. However, WSC steel ropes are less flexible than those with fiber cores. IWRC is short for independent wire rope core, which strengths the rope, reduce tensile stress in individual wires as well as makes the ropes more resistant to crushing. At the same time, IWRC wire ropes have the maximum heat resistance than others FC or WSC ropes.

IWRC is short for independent wire rope core, which strengths the rope, reduce tensile stress in individual wires as well as makes the ropes more resistant to crushing. At the same time, IWRC wire ropes have the maximum heat resistance than others FC or WSC ropes.

Reviews

There are no reviews yet.