Construction and Application

- 6×7+FC,6X7+IWRC, 6×19+FC,6X19+WIRC, 6×37+FC, 6X37+IWRC for cable car, cableway towing, slope hoisting, ship, derricking, lifting, towing etc.

- 6×12+7FC,6×15+7FC,6×24+7FC for tow boat, goods net, floating transportation of wood and lashing etc.

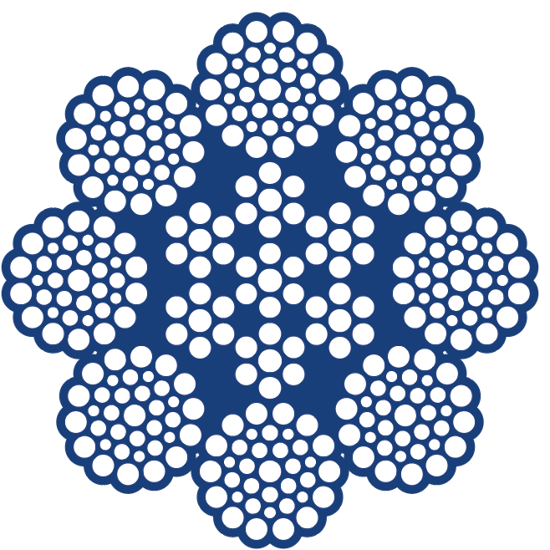

- 6×19S+FC,6×19S+IWR, 6×19W+FC,6×19W+IWR, 6×5Fi+FC,6×25Fi+IWR, 6×9Fi+FC,6×29Fi+IWR, 6×26SW+FC,6×26SW+IWR, 6×31SW+FC, 6×31S+IWR, 6×36SW+FC,6×36S+IWRC for various equipment for hoisting, derricking, lifting, towing, port load and unload, blast furnace hoisting and oil well drilling. The rope with wire core can be used under the shock load, heated and squeezed conditions.

- 18×7+FC,18×7+IWS, 18×19+FC,18×19+IWS 18×19+FC,18×19+IWS 4V×39S+5FC which are suitable for vertical well drilling hoisting, cage channel of vertical well drilling, port load and unload derrick ,and tower crane.

- 6×3×7, 7×7×7, 7×7×19 for cable of chain lock and flexible occasion.

- Wire Rope For Elevator 6×19S+NF, 8×19S+NF,6X19S+IWRC,8X19S+WIRC

- Galvanized Aircraft Cable 1×7, 1×19, 6×+FC ,6×7+IWS,6×19+FC,6×19+IWS for aircraft purpose.

Standard: GB/T8918-1996, GB 1102-74, SC 1443-86, ISO, BS, DIN, JIS, API and RRW-410D and Other.

We can supply steel wire ropes of many specifications with various surface to meet customers’needs.

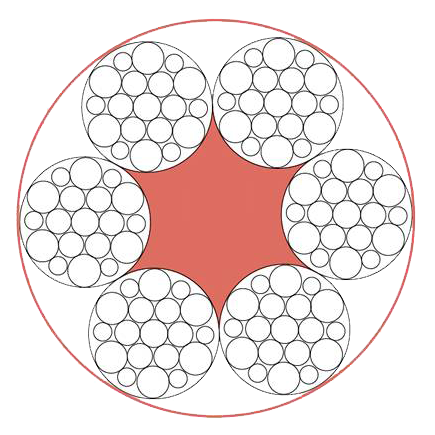

7×19 AISI316 stainless steel wire rope is used for a wide range of applications. Extremely flexible when compared to both 1×19 and 7×7, the 7×19 construction is often used where a flexible stainless steel wire rope is particularly required. 7×19 performs well for running applications. Used extensively throughout the marine industry as well as for general engineering applications, 7×19’s excellent flexibility make it a favourite for control cable and a variety of marine rigging applications, examples of which are shown below:

- Applications

- Control cables

- Guardrail

- Standing rigging

- Running rigging

- Steering cable

- Marine/Saltwater environment

- Sewage treatment works

- Wire rope slings

- Davit ropes

| Breaking Loads | |||

|---|---|---|---|

| Nominal Diameter | Approximate Mass | Minimum breaking loads – 1570 Mpa | |

| [mm] | [kg/m] | [kN] | [Kg] |

| 3 | 0.033 | 5.00 | 509 |

| 4 | 0.059 | 8.89 | 906 |

| 5 | 0.093 | 13.90 | 1,417 |

| 6 | 0.134 | 20.00 | 2,039 |

| 7 | 0.182 | 27.30 | 2,783 |

| 8 | 0.238 | 35.60 | 3,630 |

| 10 | 0.372 | 55.60 | 5,669 |

| 12 | 0.535 | 80.00 | 8,157 |

| 14 | 0.728 | 109.00 | 11,114 |

How to order:

In ordering steel wire rope, you are requested to give us complete information as specified below:

a. Purpose: For which rope will be used.

b. Size: Diameter of the rope in millimeter or inches

c. Construction: Number of strands, number of wires per strand and type of strand construction.

d. Type of Core: Fiber core( FC), independent wire rope core(IWRC) or independent wire strand core(IWSC).

e. Lay: Right regular lay, left regular lay, right lang lay, left lang lay.

f. Coating: Bright(ungalvanized), galvanized or stainless, PVC or Grease.

g. Grade of wire: Tensile strength of wires.

h. Breaking Load: Minimum or calculated breaking load in tones or pounds.

i. Lubrication: Whether lubrication is desired or not, and required lubricant.

j. Length: Length of wire rope.

k. Packing: In coils wrapped with oil paper and hessian(orp.p) cloth, or on wooden reels.

l. Quantity: By number of coils or reels, by length or weight.

m. Remarks: Shipping marks and any other special requirement.

Reviews

There are no reviews yet.