Telescopic Crane Trolley Steel Wire Rope LKS 8-1 P Should not used with a swivel

Telescopic cranes are mobile in the sense that they transport goods and items in aflexible manner. Also since telescopic cranes are further equipped with height adjustments, when itcomes to hauling and transferring the goods from one place to another, the problems related to height arecompletely eradicated.

General and High Performance Wire Rope. The use of wire rope worldwide has undoubtedly changedwhat the lifting and rigging industry is today. Wire rope is used for crane ropes, mooring lines, drill lines, hoist ropes, drag lines, and boom lines to name a few applications.

- Rope category number (RCN) 09 according to ISO 4309

- Ordinary lay

- Zinc-coated class B standard

- Should not used with a swivel

- Special lubrication

- Plastic padding

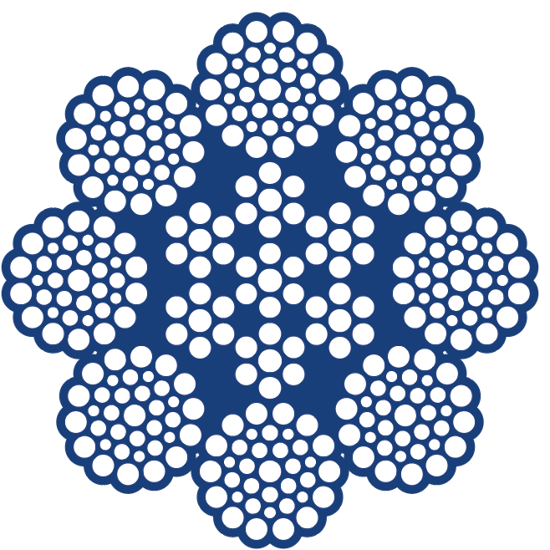

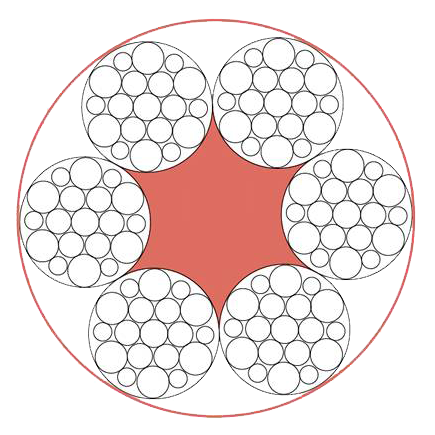

Our LKS 8-1 P is a non-rotation- resistant hoisting rope with plastic padding and 8 strands in the outer layer.

Technical Data

| Ø | Weight | Metallic cross-section |

MBK 1770 | MBK 1960 | |

|---|---|---|---|---|---|

| mm | kg/100m | mm2 | kN | kN | |

| 10 | 42.6 | 47.9 | 74.8 | 82.9 | |

| 11 | 51.6 | 57.9 | 90.5 | 100 | |

| 12 | 61.4 | 69.0 | 108 | 119 | |

| 13 | 72.0 | 80.9 | 126 | 140 | |

| 14 | 83.5 | 93.9 | 147 | 162 | |

| 15 | 95.9 | 108 | 168 | 186 | |

| 16 | 109 | 123 | 192 | 212 | |

| 18 | 138 | 155 | 242 | 268 | |

| 20 | 170 | 192 | 299 | 331 | |

| 22 | 206 | 232 | 362 | 401 | |

| 24 | 245 | 276 | 431 | 477 | |

| 26 | 288 | 324 | 506 | 560 | |

| 28 | 334 | 375 | 587 | 650 | |

| 30 | 384 | 431 | 673 | 746 | |

| 32 | 436 | 490 | 766 | 848 | |

| 34 | 493 | 554 | 865 | 958 | |

| 36 | 552 | 621 | 970 | 1074 | |

| 38 | 612 | 688 | 1075 | 1191 | |

| 40 | 679 | 762 | 1191 | 1319 | |

| 42 | 748 | 841 | 1313 | 1454 | |

| 44 | 821 | 922 | 1441 | 1596 | |

| 46 | 894 | 1005 | 1570 | 1739 | |

| 48 | 974 | 1094 | 1710 | 1893 | |

| 50 | 1075 | 1187 | 1855 | ||

| 52 | 1143 | 1284 | 2006 |

How to order:

In ordering steel wire rope, you are requested to give us complete information as specified below:

a. Purpose: For which rope will be used.

b. Size: Diameter of the rope in millimeter or inches

c. Construction: Number of strands, number of wires per strand and type of strand construction.

d. Type of Core: Fiber core( FC), independent wire rope core(IWRC) or independent wire strand core(IWSC).

e. Lay: Right regular lay, left regular lay, right lang lay, left lang lay.

f. Coating: Bright(ungalvanized), galvanized or stainless, PVC or Grease.

g. Grade of wire: Tensile strength of wires.

h. Breaking Load: Minimum or calculated breaking load in tones or pounds.

i. Lubrication: Whether lubrication is desired or not, and required lubricant.

j. Length: Length of wire rope.

k. Packing: In coils wrapped with oil paper and hessian(orp.p) cloth, or on wooden reels.

l. Quantity: By number of coils or reels, by length or weight.

m. Remarks: Shipping marks and any other special requirement.

Reviews

There are no reviews yet.